How Plastic Bulk Containers Can Improve Stock Tracking Accuracy

Wiki Article

[=image]

[/video]

[=mkeyword]Shop Bulk Plastic Containers[/mkeyword]

A Comprehensive Overview to Selecting the Right Bulk Containers for Optimal Storage Space and Transport

[#video]Choosing the appropriate mass containers is a crucial choice for businesses associated with storage and transportation. Different elements affect this option, including product compatibility and dimension requirements. Various industries have one-of-a-kind demands that have to be fulfilled to ensure safety and security and effectiveness. Comprehending these components can considerably affect logistics and product stability. The following areas will discover crucial considerations and finest practices carefully, exposing what genuinely matters in container choice.Comprehending Various Sorts Of Mass Containers

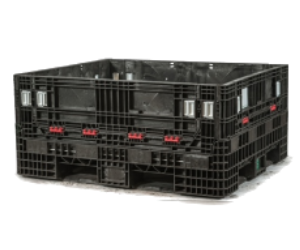

[#image]Mass containers work as essential devices in the storage and transport of different products, varying from liquids to solids. These containers are available in diverse kinds, each designed for certain applications. Common types include Intermediate Bulk Containers (IBCs), which are excellent for carrying granules, liquids, or powders. Totes, an additional variant, appropriate for both fluids and solids and can be stacked for efficient storage space. Furthermore, bulk bags, typically made from woven textile, are used to manage completely dry mass materials. For strong products, bulk containers offer sturdy, stackable alternatives that take full advantage of room. Each kind of bulk container serves a distinct function, assisting in efficient movement and storage, while guaranteeing safety and compliance with sector criteria. Recognizing these options is important for effective logistics administration.Advantages and Downsides of Usual Bulk Container Options

When examining bulk container options, it is vital to ponder both their negative aspects and advantages. As an example, inflexible containers, such as steel or plastic containers, supply durability and protection versus environmental elements, but they can be much heavier and less flexible regarding storage. On the other hand, flexible containers, like bulk bags, are lightweight and simple to manage; however, they might not offer the exact same level of defense for delicate products - [#mkeyword]. Additionally, some containers are designed for certain products, which can enhance performance but limitation flexibility. Eventually, the option of bulk container depends on stabilizing these drawbacks and advantages to fulfill the specific storage and transportation needs of the products involvedTrick Factors To Consider for Choosing Mass Containers

Choosing the best mass container calls for cautious factor to consider of a number of important elements, as the choice can greatly influence both effectiveness and safety and security throughout storage and transport. Initially, the product of the container ought to align with the nature of the items, guaranteeing compatibility to stop contamination or destruction. Next, the container's size and capability need to match the quantity of items being kept or transported, enhancing room use. Additionally, the weight of the container is crucial for both handling and transport costs. Durability and resistance to ecological variables are very important for maintaining item integrity. Lastly, compliance with sector policies and standards need to be verified to stay clear of lawful consequences. By examining these variables, businesses can make educated choices that boost operational effectiveness.Industry-Specific Bulk Container Demands

[#image]Different industries enforce specific demands for mass containers based upon the nature of the products dealt with and the regulative landscape they run within. As an example, the food and beverage sector mandates containers that are certified with health and wellness laws, assuring they are non-toxic and easily cleanable to stop contamination. Alternatively, the chemical industry typically requires containers that can withstand harsh materials, necessitating products like high-density polyethylene or steel. In pharmaceuticals, mass containers have to stick to rigid standards to guard product integrity and guarantee traceability. Furthermore, industries such as farming may focus on containers that facilitate oygenation or moisture control, while the building and construction industry might prioritize resilience and load-bearing capacity. Each need shows the one-of-a-kind challenges and compliance requirements of the corresponding industry.Best Practices for Preserving Item Integrity Throughout Storage and Transport

Maintaining item stability during storage and transport is vital, as even minor mishandling can result in considerable losses or top quality deterioration. To ensure optimal problems, temperature and humidity levels need to be carefully kept track of, especially for sensitive products. Using suitable bulk containers created for specific products is important, as these containers provide required defense against contamination and physical damages. Regular inspections of containers and storage space facilities can aid identify prospective concerns before they escalate. Additionally, proper labeling and documents streamline the managing procedure, minimizing the risk of mistakes. Educating employees in ideal practices for dealing with and delivering items additionally safeguards integrity, making certain that products reach their destination in the desired problem. Executing these best practices can substantially enhance general effectiveness and dependability.Regularly Asked Concerns

What Are the Prices Related To Mass Container Rental Versus Acquisition?

The costs related to mass Reusable Bulk Plastic Containers container rental usually include routine fees and prospective damage costs, while acquiring includes a greater upfront financial investment yet removes recurring rental costs. Each choice's overall cost varies based on usage period.How Can I Customize Bulk Containers for Details Products?

To customize mass containers for certain products, one can customize dimensions, materials, and attributes such as air flow or insulation. Branding options, color coding, and classifying further improve performance and recognition for efficient storage and transportation.

Are There Eco-Friendly Bulk Container Options Available?

Green mass container options are offered, consisting of naturally degradable plastics, recycled products, and reusable designs. These alternatives minimize ecological effect while keeping performance, attracting companies dedicated to sustainability and liable source management in their operations.What Is the Ordinary Life-span of Different Mass Containers?

The ordinary life expectancy of bulk containers varies commonly; plastic containers last 5-10 years, steel options can last 10-20 years, while wood containers normally have a life-span of 3-7 years, depending on usage and upkeep.

Just how Do I Make Certain Compliance With Rules for Mass Container Use?

To guarantee conformity with guidelines for bulk container use, one should on a regular basis examine and comprehend appropriate legislations, keep appropriate documentation, conduct safety and security audits, and carry out training programs for employees dealing with these containers. - [#mkeyword]Mass containers offer as important devices in the storage and transportation of different products, varying from fluids to solids. Each type of bulk container offers a distinctive feature, promoting reliable movement and storage, while making certain security and conformity with industry requirements. Various industries enforce details requirements for bulk containers based on the nature of the products dealt with and the regulative landscape they operate within. Utilizing proper mass containers developed for certain products is important, as these containers offer essential security against contamination and physical damage. To personalize bulk containers for certain products, one can change measurements, products, and attributes such as air flow or insulation.

Report this wiki page